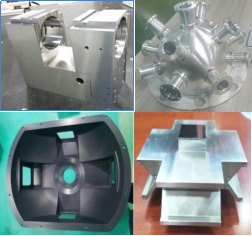

All kinds of hardware machinery, non-standard, precision parts processing

Mainly engaged in all kinds of mechanical precision parts processing, structure complex non-standard parts customized processing, automation and mechanical equipment parts processing. Electronic communication&5GParts processing, automobile & New energy parts processing, medical machinery parts processing, aerospace&Uav and other military parts processing, all kinds of precision mold parts processing, all kinds of tooling clamp fixture & Test fixture processing, etc. One-stop service for bending, welding and surface treatment.

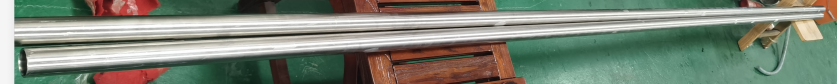

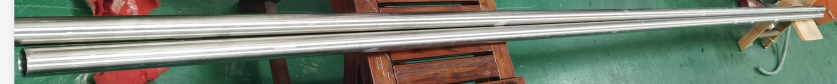

Measuring 4.2 meters in length and 30.5mm in outer diameter Nuclear steel tube inner wall machining grinding0.08~0.20mm(High precision machining to solve the case2)

France's largest nuclear steel pipe manufacturerVallourec Valurek。

Problem spot:steelPipe specifications, length respectively3.8meter、4.2Meters, outside diameter30.5mm, Tube inner wall, rough, indentationisodynia,The quality is not qualified after secondary processing and stretching. Once it is defective, it can only be scrapped (This nuclear steel pipe is imported from Germanymaterial,The value is expensive and the loss of scrap is significant),The customer has been unable to solve the loss caused by this defect.

Improve the solution

1、According to the problems and troubles raised by the customer, the specifications of defective steel pipes provided by the customer are respectively3.8meter、4.2Meters, outside diameter30.5mm, Wall thickness3.48~3.58mm,Tube inner wall, rough, concaveConvex unequal bad, the inner wall of the tube processing grinding0.08~0.20mm,Smooth and trim the inner wall of the tubeTube inner wall, rough, concaveConvex inequality is bad.

2、Our company research and special, Fully automatic processing method and technology,will3.8Meter length、 4.2Meters long, outside diameter30.5mm,Wall thickness3.48~3.58mmNuclear steel pipe,Inner wallProcess and grind away0.08~0.20mm。Guaranteed and corrected for nuclear steel pipeInner wallconcentricity,Inner wallRough and concaveConvex unequal undesirable and secure inner wallsmooth,roughness Ra<1.6 .

Improvement tracking

After the above nuclear steel pipe has been processed and repaired by our company, the customer still maintains the same process as before. After the secondary drawing processing, the rate of good products has changed from before40%Elevate to98.5%, The improvement effect is remarkable, which greatly improves the production efficiency of customers and greatly reduces the bad cost, and is highly recognized by customers.

Improve the former nuclear steel pipe&Compared with the improvement

- The wall thickness of the steel pipe is very uneven,

The standard is 3.5mm.

The actual wall thickness before processing is3.48~3.58mm ( The wall thickness is very uneven, Maximum deviation0.1mm,Obvious eccentricity )

After processing and grinding Wall thickness dimension,3.40~3.49mm,One side wears off the wall thickness 0.09mm

(Measurement of pipe wall thickness before and after machining)

( The inside diameter is smaller than the middle, Large inner diameter in the middle, The inside diameter is smaller than the middle)

Incoming screw marks before processing After processing, the effect is good, the inner wall without spiral indentation