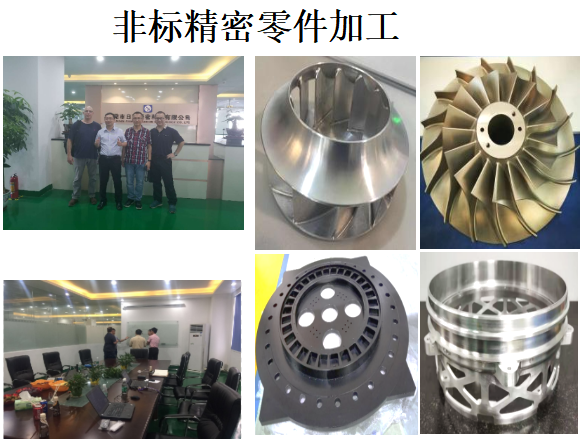

All kinds of hardware machinery, non-standard, precision parts processing

Mainly engaged in all kinds of mechanical precision parts processing, structure complex non-standard parts customized processing, automation and mechanical equipment parts processing. Electronic communication & 5G parts processing, automobile & New energy parts processing, medical machinery parts processing, aerospace&Uav and other military parts processing, all kinds of precision mold parts processing, all kinds of tooling clamp&Test fixture processing, etc. One-stop service for bending, welding and surface treatment.

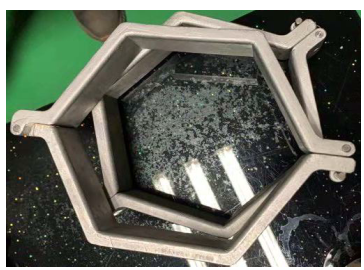

316LStainless steelmaterialmaterialcastingAnd precision machining(substituteFranceImported parts,High precision machining to solve the case

Information content and problem description

France's largest nuclear steel pipe manufacturerVallourec Valurek, Stainless steel below316LMaterial, hexagonal pack fixture(Used for nuclear steel pipe processing)。

Previously, this fixture was imported from France. Due to large consumption, short cycle and high import cost, the customer asked our company to overcome difficulties and make a replacement for foreign imports.

The application requirements and dimensional accuracy of the fixture are very high15The fixed role of the rice core steel pipe in the manufacturing process, and the repeated use of a certain life at high temperature without wear and deformation, not only requires very high dimensional accuracy of the fixture, but also requires very high and stable material of the fixture.

Product processing difficulty and requirements

Hexagonal bag fixture requirements, the fixture pin assembly, repeatedly open and then buckle, requirementsThe 6 included angles should be symmetrical and consistent, flatness and parallelism Required accuracy in0.01mm, And in the process of high temperature environment repeatedly used a certain life, not wear or deformation, still to maintain dimensional accuracy. The surface of the fixture should reach the highlight mirror to protect the nuclear steel pipe from scratches during manufacturing.

Settlement effect

Although customers have very strict requirements and use of hexagonal bag fixture, whether it is appearance, dimensional accuracy, and materials, customers have very high requirements, but we account for from the customer's point of view, its efficiency and cost for customers, we challenge stainless steel316L, Open mold casting, againCNCProcessing in place, we propose and successfully solve the production, direct savings for the customer60%At the same time, it also greatly improves the production efficiency and cycle, and finally gets the sincere recognition of customers, but also shows our special technical advantages and the spirit of customer service concept.

Rusty steel316L 1/5000 translation openMold, casting wool embryo

CNCaddWork in place

1. Hexagonal bag fixture requirements, the fixture pin assembly, repeatedly open and then buckle, the requirements of the 6 included angles to corresponding symmetry, flatness, parallelism Required accuracy in0.01mm, And in the process of high temperature environment repeatedly used a certain life, not wear or deformation, still to maintain dimensional accuracy. The surface of the fixture should reach the highlight mirror to protect the nuclear steel pipe from scratches during manufacturing.

Hexagonal bag products, Stainless steel 316L casting material composition test report (test results meet the requirements)